Input Files

Model Files With AMS Timestep Control (0.9 MB)

...

Model Files With CST Timestep Control (0.9 MB)

Introduction

Blow molding with Advanced Mass Scaling (AMS).

The aim of this example is to introduce high quality time step control Advanced Mass Scaling (AMS). Time step will be computed by OpenRadioss. Small element sizes may lead to small time step and; therefore, occupy many CPU sources. Increase time step could use time step control; but using old option of time step control will for example increase the mass or kinematic energy. If the increase is not small enough, it will affect the solution, but with this high-quality time step control AMS, there is no change in inertia effects on translational global acceleration, non-diagonal mass added. With AMS similar results are received, like the old one, but with much less computation time.

...

Options and Keywords Used

Keyword documentation may be found in the reference guide available from

...

Advanced Mass Scaling (/AMS)

Time Step for Advanced Mass Scaling (/DT/AMS/Iflag)

TYPE7 interface (/INTER/TYPE7)

TYPE7 interface has been defined between mold and plastic parison with friction 0.7.

Visco Elastic Plastic Piecewise Linear Material law (/MAT/LAW66)

Shell property (/PROP/TYPE1 (SHELL))

Rayleigh damping (/DAMP)

Rigid body (/RBODY) and Boundary condition (/BCS)

Using rigid body, two molds have been fixed in all direction of rotation and translations of y-direction and x-direction. They are only free in z-direction (translation).

Impose displacement (/IMPDISP)

Two molds are moved in opposite directions with imposed displacement.

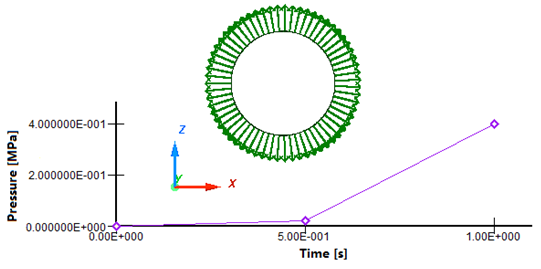

Pressure Load (/PLOAD)The air pressure on the plastic parison is modeled using pressure load /PLOAD from inside towards outside.

Model Description

A hollow plastic parison (tube-like) has been formed. Then the parison is clamped into a mold and air is pumped into it.

...

The plastic parison using visco elastic plastic piecewise linear material (/MAT/LAW66), with the following characteristics:

...

Model Method

Blow molding using AMS will be modeled as:

Define /AMS in Starter. Select the part group which will use AMS. If the part group has not been specified, then the whole model will use AMS.

Use /DT/AMS in Engine. For example:

Code Block /DT/AMS 0.67 1.15e-4

Results

The following figures show the plastic strain, von Mises stress on plastic parison.

...

Performance

Using the AMS technique, CPU time is reduced by a factor of approximately 3, in this case.

...

It shows at time 0.4s for the same speed up factor with AMS you get more accurate results compared with no mass scaling test than with nodal mass scaling.

Conclusion

To obtain a CPU saving factor of about 3, the target time step should be about 10 times higher than the one without AMS; AMS treatment itself is taking some CPU cost.

...

| Info |

|---|

Note:

|

See Also

Keyword documentation may be found in the reference guide available from

...